Vibrating Screeners Types & Working Principle

Construction vibrating screens are vital equipment in the construction industry. They are used to remove debris and other materials from construction sites. Construction vibrating screens come in many different types, each with advantages and downsides. This article will discuss the three most common construction vibrating screener kinds and their working mechanisms. Stay tuned for more! If you are looking for a vibrating screen machine, please visit our website for more information.

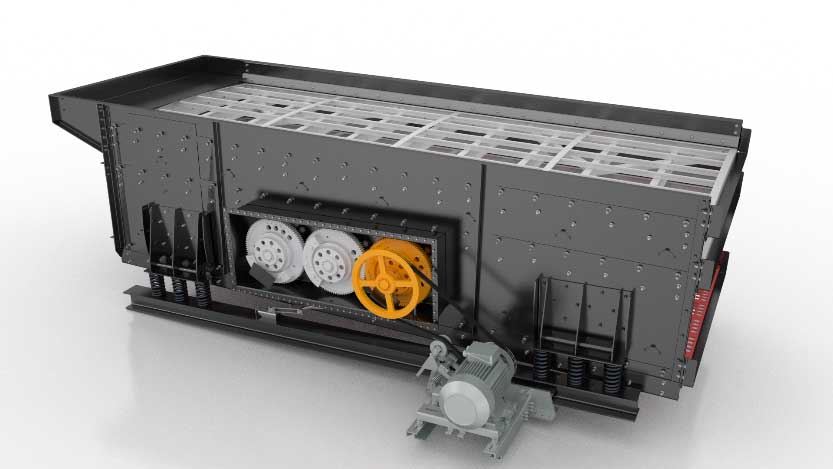

What is a vibrating screen machine?

Construction vibrating screens are widely operated in various industrial and commercial applications. They are used to screen materials such as rocks, concrete, and other objects from large pieces. The primary applications for construction vibrating screens are in demolition, earthmoving, and road building. Construction vibrating screens are also found in mining, power generation, and petrochemical production.

Construction vibrating screeners can be categorized by the type of object they are used to screen. There are slurry construction vibrating screens that use water as the liquid medium, solid-supported construction vibrating screens that use a mesh or netting support system, and air-supported construction vibrating screens that use fans to create airflow over the screen. Construction vibrators also come in various sizes and shapes to meet specific needs.

How does a vibrating screen appliance work?

Construction vibrating screen appliances are designed to remove large objects from a construction site or process materials quickly and efficiently. They work by suspending an object in a vibration field and removing it.

The appliance is attached to a platform that moves back and forth along the object being held. The vibrations cause the object to move toward the platform’s edge, where it can be easily removed. Construction vibrating screens can be used for various applications, including mining, logging, and infrastructure construction.

The efficiency of these appliances is due in part to their design. They use less energy than traditional screens and can handle larger objects than other screens. This makes them ideal for use on construction sites where resources are limited.

The working principle of vibrating screen for sand

The vibrating screener for sand is a new and innovative technology that has the potential to improve the efficiency of sand mining. The vibrating screener uses a series of metal plates that move back and forth along a steel beam, creating vibrations that reduce the amount of sand needed to be screened.

The vibrating screener effectively removes large particles from the sand, making it a more efficient screening method than traditional methods such as sifting. It has the potential to save both time and money for companies that mine sand; in fact, it has been estimated that using the vibrating screener could save companies as much as 50% on their screening needs.

Main vibrating screen types

Construction vibrating screens screen materials passing through the machine horizontally or vertically. There are three main construction vibrating screener types:

-Rotational Vibrating Screener: This screener is generally used to screen rocks, soil, and other large objects. It uses a circular motion to move the object through the screen.

-Pneumatic Vibrating Screener: This type of screener is operated to screen rocks, soil, and other large objects. The object is moved through the screen by air pressure.

-Friction Vibrating Screener: This screener is used to screen rocks, soil, and other large objects. The object is pushed through the screen by rubbing against a surface.

How to choose a good vibrating screener for my construction project?

When selecting a vibrating screener for your construction project, it is essential to consider the specific needs of the task. Vibrating screener use varies significantly based on the type of construction site and material being screened. For example, vibrating screeners are commonly used for concrete and asphalt screening but are less effective on metal and other hard surfaces.

Here are three tips for choosing the best vibrating screener for your construction project:

1. Consider the type of construction project you’re working on. The vibrating screener’s effectiveness depends on the type of material being screened. For example, a vibrating screener used in demolition is more effective than one used in building construction.

2. Choose a vibrating screener appropriate for your project size and budget. Larger projects will require a more powerful vibrating screener, while smaller projects may be able to use a less powerful model. Be sure to factor in the cost of replacement filters as well as the price of the machine itself.

3. Consider how often you’ll use the screener. A less expensive model may be suitable if you only use it occasionally. However, if you’re using it more frequently, something more durable may be necessary.

4. Calculate how frequently the screener will need to be replaced and factor that into its cost. Screens typically last around six months before they need to be replaced, but this varies depending on the type and size of the screen used. Replacement costs can range from around $200-$1,000+.

5. Be sure to thoroughly research the different types of machines available before making a purchase. There are various models and sizes on the market, so it is crucial to find one compatible with your specific needs.

6. Take into account your budget. Vibrating screens range in price from around $1,000 to over $10,000. Getting a machine that fits your budget and meets your specific needs is essential.